Production

Compliance with German standards, attention to detailCOMPONENTS

German engineers closely monitor the technological innovations in the metalworking industry.

Due to regular modernization, KRAUF components, by their performance, outperform the original parts, while at the same time being advantageously different from them at a price.

Manufactured products meet the European quality standards.

Serial production on high-precision modern equipment.

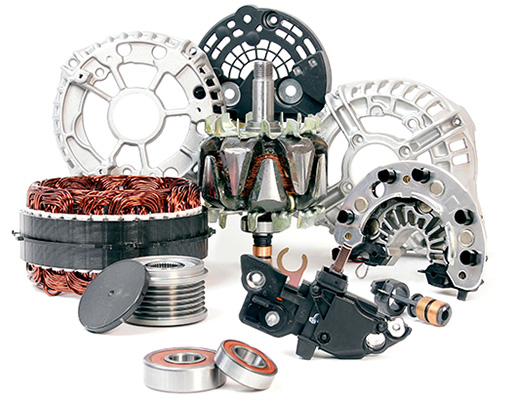

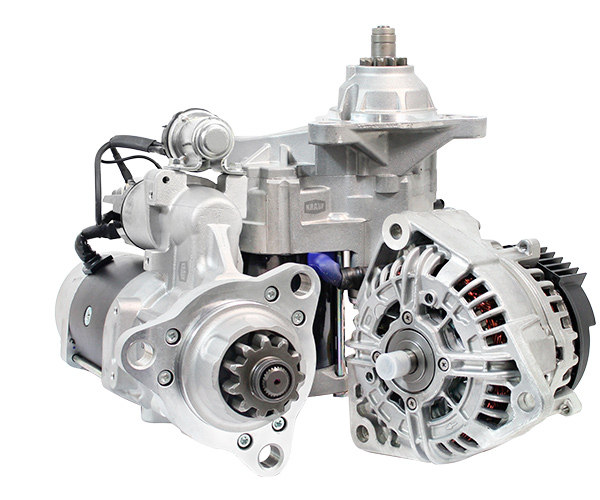

STARTER MOTORS AND ALTERNATORS

Full cycle of production of starter motors and alternators.

All alternators and starter motors are certified and passed operational tests.

Quality is controlled by German technologists and engineers.

Full functional compliance and interchangeability with original parts.

FUEL PUMPS AND MODULES

Under the trademark Krauf, two types of gasoline fuel pumps are produced, electric and mechanical.

Innovative technologies, strict quality control, and the use of process materials make Krauf fuel pumps reliable.

Krauf gasoline fuel pumps are repairable, since they have a modular design of mechanical components. Fuel pumps are easy to operate and maintain.

Design features ensure efficient operation of pumps at temperatures from -60 ° C to + 50 ° C.

In the production of KRAUF products, high requirements for the selection of components for their products are used, so the electric fuel pump in the module has passed a full cycle of factory tests on the impact of vibration and shock loads.

Thanks to the use of advanced technologies, high-quality fuel pumps will ensure the uninterrupted operation of the engine.

TURBOCOMPRESSORS

The production process is built into a consistent technological chain, engineering developments are used to improve products.

For resistance to high temperatures and resistance to fracture, the turbocharger housing is made of spheroidized cast iron.

Technologies are used that allow changing the geometry of the turbine, which allows you to redirect the geometry of the turbine nozzle, as a result of which the engine power increases many times over.

The mass of the turbine is reduced by turning and replacing parts with others made from lighter materials, high-strength heat-resistant and light ceramics.

In the manufacture of steel rings, separate calculations are made, as a result of which a particularly careful calibration takes place to evenly distribute the load on the bearing.

Turbine wheels are coated with a nickel alloy and are melted from heat-resistant materials, which allows the unit to operate at temperatures up to 76 ° C.

Turbine wheels resist corrosion, deformation and have a high degree of wear.

All alloys are selected taking into account the characteristics of various aggregates. To perform the work, we resort to the method of vacuum or sand casting.

We meticulously evaluate the quality with which processing is carried out in order to increase wear resistance and resistance to high temperatures.

Quality performance of the turbocharger is achieved through precise finishing. The size and properties of the surface are taken into account most accurately.

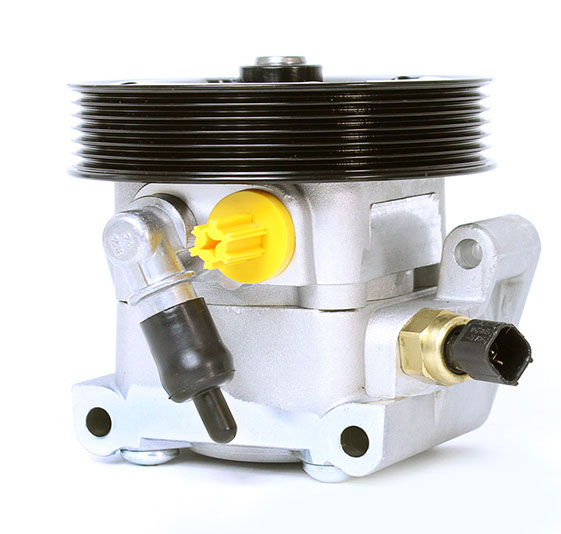

POWER PUMPS

The range of power steering pumps covers 80% of the Russian automotive market.

We are constantly working on expanding the range in the steering segment.

The painstaking selection of materials and the high technical equipment of the production lines guarantee the quality.

The testing technologies and quality requirements applied by German engineers do not allow compromises in safety issues.

By installing a power steering pump from KRAUF, you can be sure that replacement will not be required soon.

In case of repair, the engineers took care of all the necessary mechanisms. There are complex and rare components available.

STEERING RACKS

The choice of material and the high technical equipment of the production lines guarantee the quality of the products. The testing technologies and quality requirements applied by German engineers do not allow compromises in safety issues.

The cold forging process used in the production of the steering rack makes it so strong that it effectively resists strong side impacts.

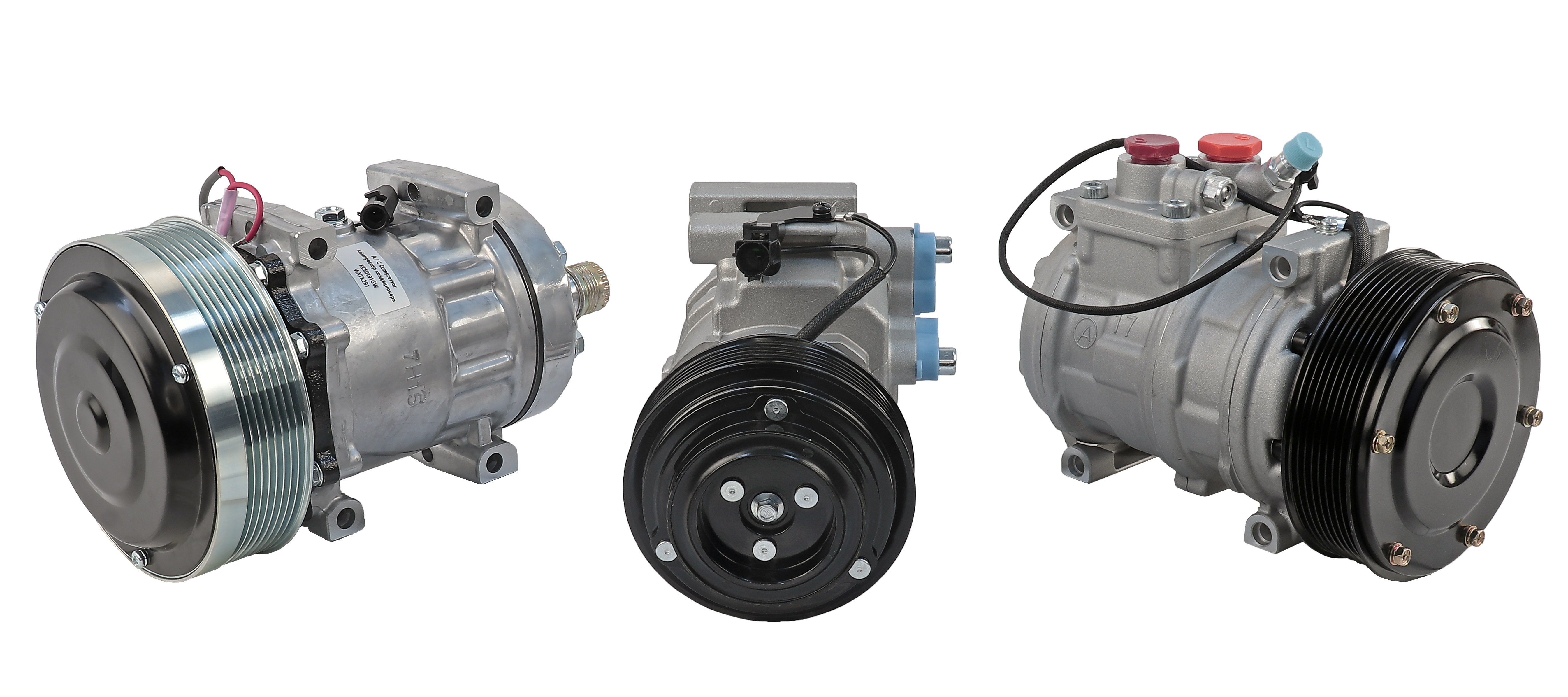

AIR CONDITIONING COMPRESSORS

The air conditioner compressors is the main element of the air conditioning system.

In modern car air conditioning systems, various types of compressors are used, differing in power, performance, etc.

To assemble a high-performance compressor, high-quality parts with extremely precise dimensions are required. Therefore, each batch of components undergoes quality control of manufacturing and dimensional conformity. Some components are manually checked by a specialist using electronic micrometers.

All manufactured air conditioning compressors are tested on the stands in accordance with the highest quality standards, where parameters such as durability, performance, noise level under load are checked.

Krauf compressors are widely used in post-factory installations in passenger cars and commercial vehicles.

Also, our air conditioner compressors are in great demand for agricultural and special equipment, because. have proven themselves to be stable even in the most extreme conditions (up to +50C), helping the driver to perform their work clearly and efficiently.

HEATER MOTORS

KRAUF heater motors are manufactured in accordance with strict product quality requirements, undergoing control at every stage of production.

Products are constructed using high-strength composites that meet the latest manufacturing trends and ensure long service life.

Modern, high-quality materials ensure quiet, smooth operation of the heater motor and increase the efficiency of temperature control, even in the harshest weather conditions.

The wide selection of products in our catalog is suitable for many car brands and allows you to choose a product that fully matches your vehicle.

ENGINE COOLING FANS

KRAUF automotive cooling fans have compact structure, easy installation, large air volume, high pressure and low vibration.

Manufactured to the highest quality standards and under the strict supervision of highly qualified specialists.

Advanced ABS blade design gives our fans a lightweight yet durable design for the most efficient cooling. To reduce energy consumption without losing torque, we use only high-performance magnets, and unique brush and bearing technology ensures ultra-low noise levels.

KRAUF cooling fans perform their function perfectly, ensuring that the engine operates at the correct temperature.

They are an excellent alternative to original products.

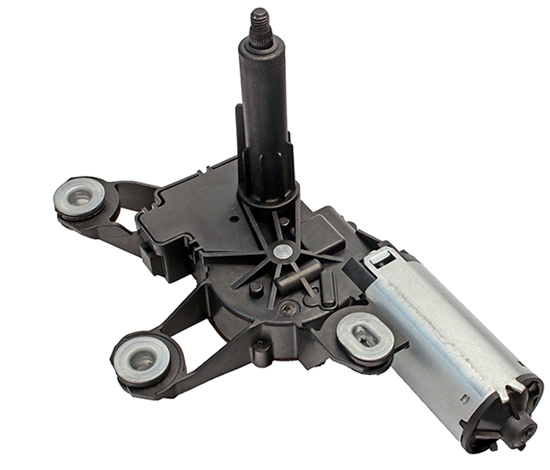

WINDOW WIPER MOTORS

KRAUF windshield wiper motors are made from the most durable materials available to ensure maximum performance and durability beyond the original parts.

The reliable design of the product guarantees high torque and resistance to adverse external conditions (dust, rain, snow).

We offer a wide range of windshield wiper motors to suit different requirements and vehicles. All products are designed and manufactured by professionals and are designed to last for many years of service.

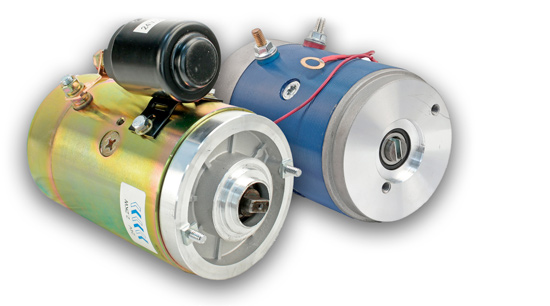

DC motors

A DC motor is a DC electric motor that converts electrical energy into mechanical energy.

KRAUF DC motors are manufactured on high-precision equipment, each component part undergoes quality control both manually and on specialized equipment before assembly. During operation, they withstand high and prolonged loads.

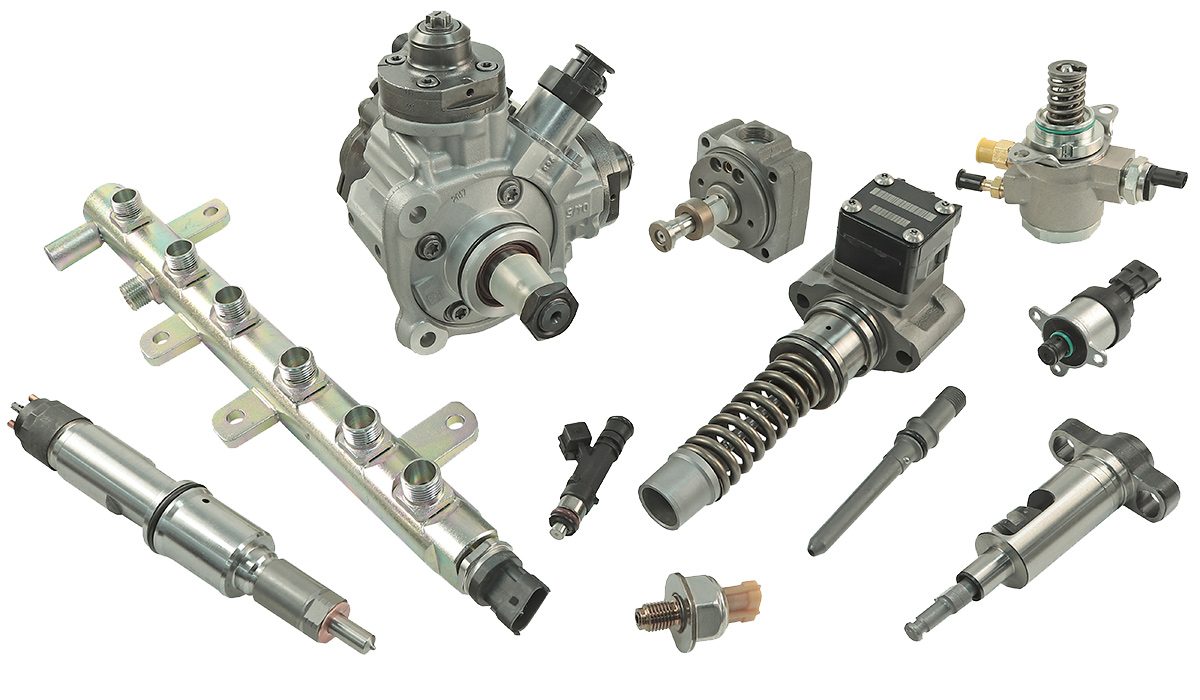

Fuel equipment

KRAUF fuel equipment is quite modern, sophisticated and precise, and exclusively high-quality materials and the latest equipment are used for its manufacture. Only those products that have passed the strictest quality control and fully correspond to the original are available for sale.

KRAUF fuel equipment is represented by a wide range of products:

- petrol and diesel injectors;

- fuel injection pumps are modern high-pressure fuel pumps that are used by the system to supply fuel under high pressure;

- nozzle pumps;

- sensors and control units;

- plunger and spray pairs;

- discharge valves, fittings, repairs. kits and other components.